Capabilities

- Experiment with operating conditions and scenarios

- Easily change system input data, including valve positions, compressor or fan operation, control set points, pressures, temperatures, and more

- Model a wide range of system components from handbook empirical sources, or input manufacturer data

- Simulate ideal or real gases

- Choose between isothermal, adiabatic or generalized heat transfer conditions

- Conduct flow analysis with high velocities including sonic choking

- Compile libraries of custom components, pipe materials, and fluids to save time, share common data among your team, and avoid input error

- Assemble non-reacting mixtures and analyze dynamic mixtures resulting from intersecting pipe flow streams

- Model rotating piping systems such as those found in steam and gas turbines

- Model effects of elevation changes such as in tall structures, subsurface mines and overland pipelines

- Evaluate codes and industry standards applied in the model

Benefits

- Understand the behavior of your system

- Predict how pipes, valves, compressors, fans and other components will interact with each other

- Evaluate the performance of new designs

- Assure all design requirements are met

- Identify and correct operational problems

- Produce less costly, more efficient, and more reliable piping systems

Applications

- Pipe and duct sizing

- Relief valve sizing and system calculations

- Compressor and fan sizing and selection

- Control valve sizing and selection

- Simulate system operation and component interaction

- Calculate choked flow

- Evaluate pipe insulation and heat transfer in pipes and heat exchangers

- Troubleshoot existing systems to determine the cause of operational problems

Features

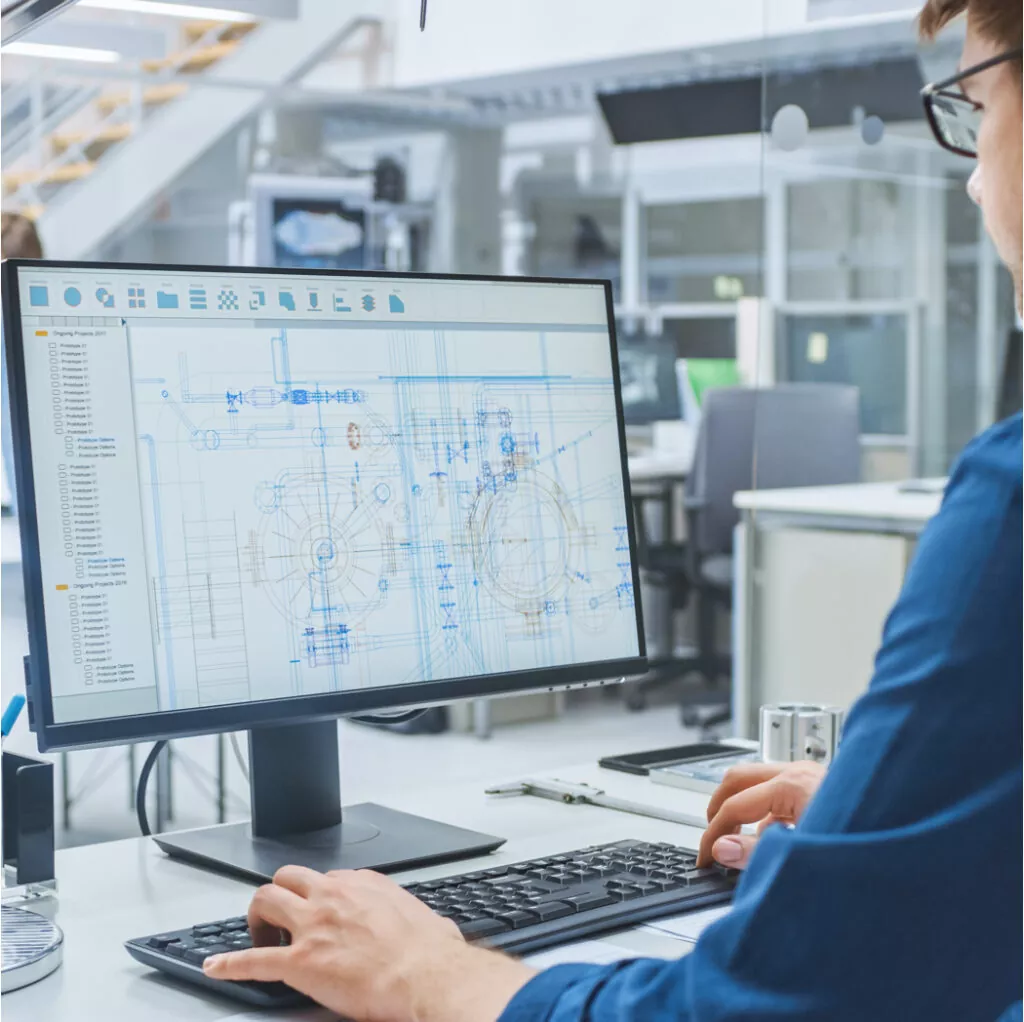

- 2D flow diagram or isometric view interface

- Advanced solution methods provide highly accurate results

- Detailed modeling for fans and compressors, control valves, heat exchangers and other components

- Conduct compressor and fan energy cost analysis

- Thermal analysis including piping heat transfer and heat exchanger modeling

- Scenario Manager tracks all design variants and operational possibilities in a single model file

- Built-in libraries of fluids (including NIST REFPROP and ASME Steam Tables) and pipe fittings which can be extended and customized

- Chempak™ add-on utility provides a thermophysical database of almost 600 gases – allows you to define nonreacting pre-mixtures and simulate dynamic flow mixing

Data Integration

- Import piping layouts and dimensional data from GIS Shapefiles, CAESAR II Neutral Files, and PCF files from a wide range of sources

- Robust Excel integration to import and export data

Add-On Modules

-

Goal Seek and Control (GSC)

Identifies input parameters that yield desired output values and simulates control functions

-

Automated Network Sizing (ANS)

Automatically size your network to meet design requirements and minimize system cost

-

Extended Time Simulation (XTS)

Models dynamic system behavior and how critical system parameters vary over time

How does it work?

AFT Arrow’s powerful solution engine simultaneously solves five fundamental equations; mass, momentum, energy, state and Mach number. It uses a modified Newton – Raphson matrix iteration method plus proprietary methods developed by AFT so you can achieve a true and rigorous compressible flow solution.

Formation

Training that meets your needs

Flumen offers several training options to suit the needs of Canadian users. Contact our experts, who can help you choose the most appropriate options for you.

Contact us

"*" indicates required fields