Capabilities

- CAEPIPE performs linear and non-linear, static and dynamic pipe stress calculations for piping systems of any complexity, in any industry. It determines structural response of pipe and pipeline systems to various types of loadings and computes stresses in accordance with numerous international codes and standards. Even steel structural analysis can be performed with CAEPIPE.

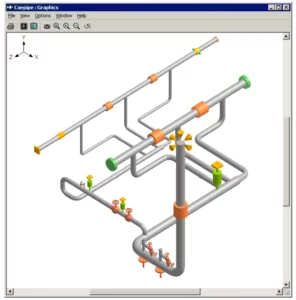

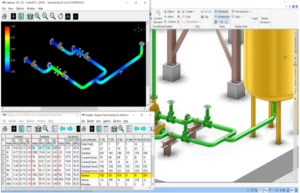

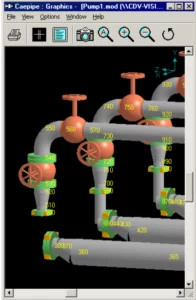

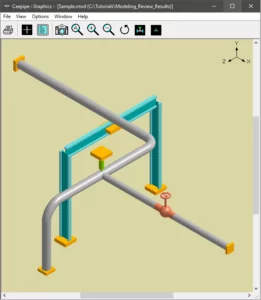

- Multiple open windows providing simultaneous visual and textual feedback on different aspects of the model. Aids rapid and accurate understanding of model details and its response to loadings.

- Dynamic updating of data across all windows (make one change in one window and all other windows reflect the change). Fewer keystrokes and mouse movements to go through; Flexibility and instant visual feedback.

- Single-click editing in Graphics window for alternative modeling. Two ways of editing model (not forced to textual screen editing only).

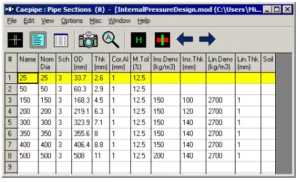

- Model straight pipes, elbows, bends, valves, concentric and eccentric reducers, tees, miters, rigid elements and more. External insulation and internal lining can be specified for pipes.

- Model expansion joints (such as slip, ball, hinge, bellows (tied and untied), gimbal, and universal joints) and elastic elements.

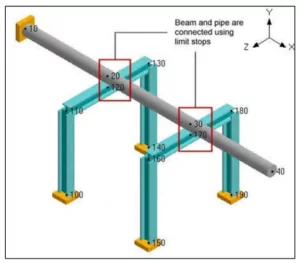

- Non-linearities. Model gaps using limit stops (such as in pipe slide/shoe assemblies), including friction at supports and expansion joints.

- Option to internally compute SIFs and Flexibility Factors (FFs) for ASME B31 pipe fittings using ASME B31J.

Benefits

- Multiply Your Productivity — Use CAEPIPE’s elegantly simple and intuitive user-interface for rapid modeling and editing, powerful analyses with quick solution times, and easy results review.

- Model and analyze in 3D for effects of weight, 10 sets of pressures and temperatures, earthquake, wind, time varying and harmonic loads, and more.

- Perform easy “what if” scenarios to evaluate alternate designs.

- Meet the requirements of piping codes (ASME B31, ASME Section III, European EN and many other international codes) and equipment standards (NEMA, API, etc.).

- Import piping geometry and design data from 3D pipe design software such as AutoCAD Plant 3D, PDMS, PDS/SmartPlant, Autoplant and more.

- Export data to major 3D piping design systems such as PDMS and CADMATIC and to PCF format.

- Create clear, formatted reports with a few clicks.

- Let them evaluate your designs using the free evaluation version of CAEPIPE, which doubles as a pipe stress model and results viewer.

- Reduce Your Costs — Choose among cost-effective pricing options, save engineering time, and optimize your design.

Industries

- Power (fossil & nuclear)

- Refinery

- Fertilizers

- Sugar & Food Processing

- Steel / Metal Process

- Aircraft and Aerospace

- Defense Industries

- Oil & Gas production (onshore & offshore)

- Chemical & Petrochemical

- Pharmaceutical

- Paper & Pulp

- Water & Waste Treatment

- Building Services

- Ship Building

Piping Codes

ANSI/ASME

- B31.1

- B31.1 (1967)

- B31.3

- B31.4

- B31.5

- B31.8

- B31.9

- B31.12

- ASME Section III Class 2

- ASME Section III Class 3

International

- British BS 806

- Canadian CAN/CSA Z183

- Canadian CAN/CSA Z184

- Canadian CAN/CSA Z662

- IGEM

- Norwegian

- French RCC-M

- French CODETI

- Dutch Stoomwezen

- Swedish

- European EN13480

Preview

Formation

Training that meets your needs

Flumen offers several training options to suit the needs of Canadian users. Contact our experts, who can help you choose the most appropriate options for you.

Contact us

"*" indicates required fields